Clint Shock

In an effort to find an alternative method of irrigating crops with high water demands in an arid region, we considered drip irrigation. Drip irrigation is the slow, even application of low pressure water to soil and plants using plastic tubing placed directly at the plants root zone.

Why consider drip irrigation?

Drip irrigation can help you use water efficiently. A well-designed drip irrigation system loses practically no water to runoff, deep percolation, or evaporation. Drip irrigation reduces water contact with crop leaves, stems, and fruit. Thus conditions may be less favorable for the onset of diseases. Irrigation scheduling can be managed precisely to meet crop demands, holding the promise of increased yield and quality.

Growers and irrigation professionals often refer to "subsurface drip irrigation," or SDI. When a drip tape or tube is buried below the soil surface, it is less vulnerable to damage during cultivation or weeding. With SDI, water use efficiency is maximized because there is even less evaporation or runoff.

Agricultural chemicals can be applied more efficiently with drip irrigation. Since only the crop root zone is irrigated, nitrogen already in the soil is less subject to leaching losses, and applied fertilizer N can be used more efficiently. In the case of insecticides, less product might be needed. Make sure the insecticide is labeled for application through drip irrigation.

Additional advantages of drip irrigation include:

- Drip systems are adaptable to oddly shaped fields or those with uneven topography or soil texture; these specific factors must be considered in designing the drip system. Drip systems also can work well where other irrigation systems are inefficient because parts of the field have excessive infiltration, water puddling, or runoff.

- Drip irrigation can be helpful if water is scarce or expensive. Because evaporation, runoff, and deep percolation are reduced and irrigation uniformity is improved, it is not necessary to "over-water" parts of a field to adequately irrigate the more difficult parts.

- Precise application of nutrients is possible using drip irrigation. Fertilizer costs and nitrate losses can be reduced. Nutrient applications can be better timed to meet plants' needs.

- Drip irrigation systems can be designed and managed so that the wheel traffic rows are dry enough to allow tractor operations at any time. Timely application of herbicides, insecticides, and fungicides is possible.

- Proven yield and quality responses to drip irrigation have been observed in onion, broccoli, cauliflower, lettuce, melon, tomato, and cotton.

- A drip irrigation system can be automated.

There are some disadvantages to drip irrigation. For example:

- Drip irrigation systems typically cost $500 to $1,200 or more per acre. Part of the cost is a capital investment useful for several years, and part is annual. Systems can be more elaborate and costly than they need to be. Growers new to drip irrigation might want to start with a relatively simple system on a small acreage.

- Drip tape or tubing must be managed to avoid leaking or plugging. Drip emitters are easily plugged by silt or other particles not filtered out of the irrigation water. Emitter plugging also can be caused by algae growing in the tape or by chemical deposits at the emitter.

- You might need to redesign your weed control program. Drip irrigation might be unsatisfactory if herbicides need sprinkler irrigation for activation. However, drip irrigation can enhance weed control in arid climates by keeping much of the soil surface dry. Tape depth must be chosen carefully for compatibility with operations such as cultivation and weeding.

- Drip tape causes extra cleanup costs after harvest. You'll need to plan for drip tape disposal, recycling or reuse.

Components and design of a drip irrigation system

A wide range of components and system design options is available. The Drip Directory lists equipment and suppliers. Drip tape varies greatly in its specifications, depending on the manufacturer and its use (Table 1). The distribution system, valves, and pumps must match the supply requirements of the tape. Tape, depth of tape placement, distance between tapes, emitter spacing and flow, and irrigation management all must be chosen carefully based on crop water requirements and the soil's properties. Drip tubing rather than drip tape is usually used for perennial crops such as grapes or poplar trees.

Table 1. A listing of different manufacturers and specifications of Drip Irrigaiton Systems.

| Manufacturer | Diameter (inches) | Wall thickness (mil) | Emitter spacing (in) | Emitter flow rates (gal/h) |

|---|---|---|---|---|

| Chapin Watermatics | 5/8, 7/8 | 4, 6, 8, 10, 15 | 2, 4, 8, 9, 12, 16, 24 | 0.125 - 0.65 |

| Drip Tape Man. and Eng. Inc. | 5/8, 7/8 | 5, 6, 7-8, 10, 15 | 4 1/4, 8 1/2, 12 3/4, 17 1/4 | 0.15, 0.21, 0.28 |

| Eurodrip | 5/8, 7/8, 1 | 6, 8, 10, 12, 15 | 8.48 | 0.16, 0.25, 0.40, 0.60, 1.00 |

| Netafim | 5/8, 7/8, 1 | 6, 8, 10, 13, 15 | 7 | 0.16, 0.21, 0.24, 0.33, 0.48, 0.60 |

| Roberts Irrigation Products | 5/8, 3/4, 7/8 | 5, 6, 8, 10, 13, 15 | 4, 8, 12, 16, 24 | 0.13, 0.18, 0.20 0.24, 0.27, 0.34, 0.50 |

| T-Systems International | 3/8, 5/8, 7/8, 1 3/8 | 4, 5, 6, 7, 8, 10, 15, 20 | 4, 6, 8, 12, 16, 18, 24 | 0.14, 0.17, 0.20, 0.22, 0.27, 0.28, 0.34, 0.40, 0.44, 0.45, 0.67 |

| ToroAg | 5/8, 7/8, 1 3/8 | 4, 6, 8, 10,12, 15 | 4, 8, 12, 16, 24 | 0.13, 0.15, 0.20, 0.27, 0.34 |

Design must take into account the effect of the land's contour on pressure and flow requirements. Plan for water distribution uniformity by carefully considering the tape, irrigation lengths, topography, and the need for periodic flushing of the tape. Design vacuum relief valves into the system.

When designing a drip system, first identify fairly similar Irrigation zones. Irrigation zones are based on factors such as topography, field length, soil texture, optimal tape run length, and filter capacity. Many irrigation system suppliers use computer programs to easily analyze these factors and design drip systems. Once the zones are assigned and the drip system is designed, it is possible to schedule irrigations to meet the unique needs of the crop in each zone.

Consider power and water source limitations. Have your water analyzed by a laboratory that is qualified to evaluate emitter plugging hazards. Water quality might create limitations and increase system costs. Filters must be able to handle worst-case scenarios.

Finally, be sure to include both injectors for chemigation and flow meters to confirm system performance.

Filters and Pumps

Every trickle counts when you are battling a water shortage. An ineffective or improperly managed filter station can waste a lot of water and threaten a drip system's fitness and accuracy.

In the western U.S., sand media filters have been used extensively for micro irrigation systems. Screen filters and disk filters are common as alternatives or for use in combination with sand media filters.

Sand media filters provide filtration to 200 mesh, which is necessary to clean surface water and water from open canals for drip irrigation. These water sources pick up a lot of fine grit and organic material, which must be removed before the water passes through the drip tape emitters.

Sand media filters are designed to be self-cleaning through a "backflush" mechanism. This mechanism detects the drop in pressure due to the accumulation of filtered particles. It then flushes water back through the sand to dispose of clay, silt, and organic particles.

Sand used for filters should be between size 16 and 20 to prevent excess back flushing. To assure enough clean water for back flushing, several smaller sand media filters are more appropriate than a single large sand media filter (Gleski, 2003).

In addition to a sand media filter, a screen filter can be used as a prefilter to remove larger organic debris before it reaches the sand media filter, or as a secondary filter before the irrigation water enters the drip tube (Figure 1). For best results, filters should remove particles four times smaller than the emitter opening, as particles may clump together and clog emitters. Screen filters can act as a safe guard if the main filters fail, or may act as the main filter if a sufficiently clear underground water source is used.

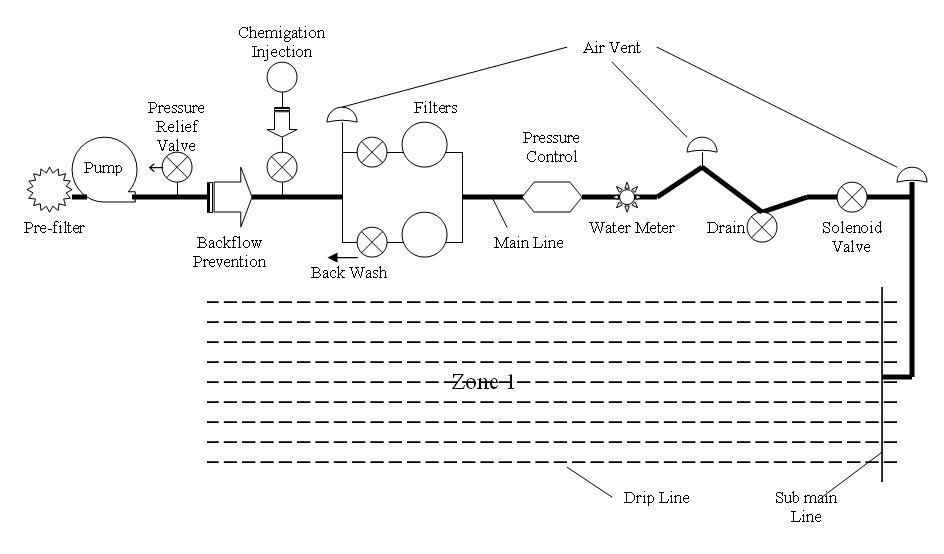

Figure 1. Drip irrigation systems with a prefilter, pump station with backflow prevention, and chemical injection site. The chemical injection site can be before or after the main filter station. A pressure control valve is recommended to adjust the water pressure as desired before it enters the drip lines. A water meter can be placed after the pressure control or between a solenoid valve and each zone. An air vent provides vacuum relief. Vacuum relief is necessary between the solenoid valve and the drip tapes to avoid suction of soil into the emitters when the system is shut off.

System Management

If a drip hose system is used on the soil surface for perennial crops over a number of years, the drip hose should be lifted periodically so that leaves, soil, and debris do not cover the hose. If the drip hose is not lifted, roots can grow over the hose, anchor it to the ground, and eventually pinch off the flow of water.

Flow of Water

Place a water flow meter between the solenoid valve and each zone and record it's gauge daily. This provides a clear indication of how much water is applied to each zone. Records of water flow can be used to detect deviations from the standard flow of the system, which may be caused by leaks or by clogged lines. The actual amount of water applied recorded on the meter can be compared with the estimated crop water use (crop evapotranspiration) to help assure efficient water management.

Watch for Leaks

Leaks can occur unexpectedly as a result of damage by insects, animals, or farming tools. Systematically monitor the lines for physical damage. It is important to fix holes as soon as possible to prevent uneven irrigation.

Chlorine Clears Clogged Emitters

If the rate of water flow progressively declines during the season, the tubes or tape may be slowly plugging, resulting in severe damage to the crop. In addition to maintaining the filtering stations, regular flushing of the drip tube and application of chlorine through the drip tube will help minimize clogs. Once a month, flush the drip lines by opening the far ends of a portion of the tubes at a time and allowing the higher velocity water to rush out the sediment.

Because algae growth and biological activity in the tube or tape are especially high during warmer months, chlorine usually is applied at 2-week intervals during these months.

If drip lines become plugged in spite of maintenance, many cleaning products are available through irrigation systems suppliers. Choose a product appropriate for the specific source of contamination.

Chemigation

Manage irrigation and fertilization together to optimize efficiency. Chemigation through drip systems efficiently delivers chemicals in the root zone of the receiving plants. Because pf the precision of application, chemigation can be safer and use less material. Several commercial fertilizers and pesticides are labeled for delivery by drip irrigation.

Injection pumps with backflow prevention devices are necessary to deliver the product through the drip lines. These pumps allow for suitable delivery rate control, while backflow prevention protects both equipment and the water supply from contamination. remember that in Oregon, water belongs to the public, not the landowner. Other safety equipment may be required; contact a drip-irrigation system supplier for details.

Fertilizer

Soil microorganisms convert nitrogen (N) fertilizers to nitrate. Nitrate is water soluble, available to plants, and subject to leaching loss. Since nitrate loss management was one of the initial reasons for our exploring drip irrigation, it is appropriate that we revisit this topic.

Typically, when irrigation is monitored closely, less nitrogen fertilizer is needed with drip irrigation systems than with furrow irrigation systems because the fertilizer is spoon-fed to the root system and little is lost due to leaching. For example, if a field is converted from furrow irrigation to drip irrigation and the amount of nitrogen fertilizer is not reduced, the crop may become excessively leafy which can inhibit curing and increase harvest costs as well as losses. Leaf tissue analysis performed by a qualified agricultural lab can help determine crop nutrition needs during the season, and tailor the N fertilizer applications to actual crop needs.

Fertilizer can be injected through the drip system. Fertilizer usually is introduced into the irrigation system in front of the filter station so the filters can remove any precipitates that occur in the solution.

Fertilizers containing sulfate, phosphate, calcium, or anhydrous or aqua ammonium can lead to solid chemical precipitation inside the drip lines, which can block emitters. Obtain chemical analysis of your irrigation water and seek competent technical advice before injecting chemical fertilizers into drip systems.

Placement of Tape

Plan for seed emergence. The drip tape must be close enough to the surface to germinate the seed if necessary, or a portable sprinkler system should be available. For example, a tape tube 4 to 5 inches deep has successfully germinated onion seeds in silt loam soil. Tape at 12 inches failed to uniformly germinate onions.

Timing and Rates

The total irrigation water requirements for crops grown with a drip system is greatly reduced compared to a surface flood system because water can be applied much more efficiently with drip irrigation. For example, with furrow irrigation, typically at least 4 acre-feet/acre/year of water is applied to onion fields in the Treasure Valley of eastern Oregon and southwestern Idaho. Depending on the year, summer rainfall, and the soil, 14 to 32 acre-inches/acre of water has been needed to raise onions under drip irrigation in the Treasure Valley.

Applying more water than plants need will negate most of drip irrigation's benefits. The soil will be excessively wet, promoting disease, weed growth, and nitrate leaching.

To determine application rates, use measurements of soil water and estimates of crop water use (crop evapotranspiration, or "ETc"). For shallow rooted crops, irrigate only to replace the soil moisture deficit in the top 12 inches of soil. It usually is not necessary to exceed ETc. Daily crop evapotranspiration estimates are available locally on our Website. For information on measuring soil water levels directly, see Irrigation Monitoring using Soil Water Tension.

Standard Maintenance

Add chlorine or other chemicals to the drip line periodically to kill bacteria and algae. Acid might also be needed to dissolve calcium carbonates.

Filters must be managed and changed as needed. Even with filtration, however, drip tape must be flushed regularly. The frequency of flushing depends on the amount and kinds of sedimentation in the tape.

Other Management Factors

Root intrusion needs to be controlled for some crops. Rodents must be controlled, especially where drip tape is buried.

Additional Resources

Drip Irrigation for Row Crops. 1994. Chanson, Schwankl, Grattan, and Prichard, University of California, Davis. Order from Cooperative Extension office, Department of LAWR, 113 Veihmeyer Hall, University of California, Davis, CA 95616, telephone (530) 752-1130.

B.C. Trickle Irrigation Manual. 1999. Van der Gulik, B.C. Ministry of Agriculture and Food Resource Management Branch. Order from Irrigation Association of British Columbia, 2300 Woodstock Drive, Abbotsford, B.C., Canada, V3G 2E5, telephone (604) 859-8222.

Fertigation, 1995, Burt, O'Connor, and Ruehr, California Polytechnic State University. Order from The Irrigation Training and Research Center, California Polytechnic State University (Cal Poly), San Luis Obispo, CA 93407, telephone (805) 756-2434.

Micro irrigation Management and Maintenance. 1998. Hassan, Farouk A.. Fresno, CA, Agro Industrial Management, 1998. The book is available from Farouk A. Hassan, Ph.D.

Irrigation & Soils Consultant, Agro Industrial Management, P. O. Box 5632, Fresno, California 93755, U.S.A. Phone: (209)224-1618, Fax: (209) 348-0721, E-mail: fahassan@aol.com

Chemigation in Tree and Vine Micro Irrigation Systems. 2001. Schwankl, L. and T. Prichard. Agriculture and Natural Resources Publication 21599. University of California, Davis, CA.

Resources on the Web:

Acknowledgements

Funding to help prepare this publication was provided in part by an Oregon Watershed Enhancement Board Grant.

Prepared by Clinton C. Shock, Superintendent, Malheur Experiment Station, Oregon State University.

June 2001, updated August 2014.